During the second half of 2015, the newly formed Ebor Automotive Systems has won nearly R1 billion rand worth of business. A significant part of this package of work, which will be delivered over the next 7 years, is for Volkswagen South Africa and includes a number of components for the relaunch of the Polo around the middle of 2017.

Ebor Managing Director Andy Dealtry comments that “This completely vindicates the considerable risk that management and shareholders took when they acquired the assets from Visteon, took on an onerous property lease and made commitments to the founding team of around 25 staff. While we were always quietly confident that we would be able to use the considerable experience and available plant, we spent much of the first year in hope without any certainty around the future. That certainty has now been realised and we are enormously excited about delivering this basket of parts”.

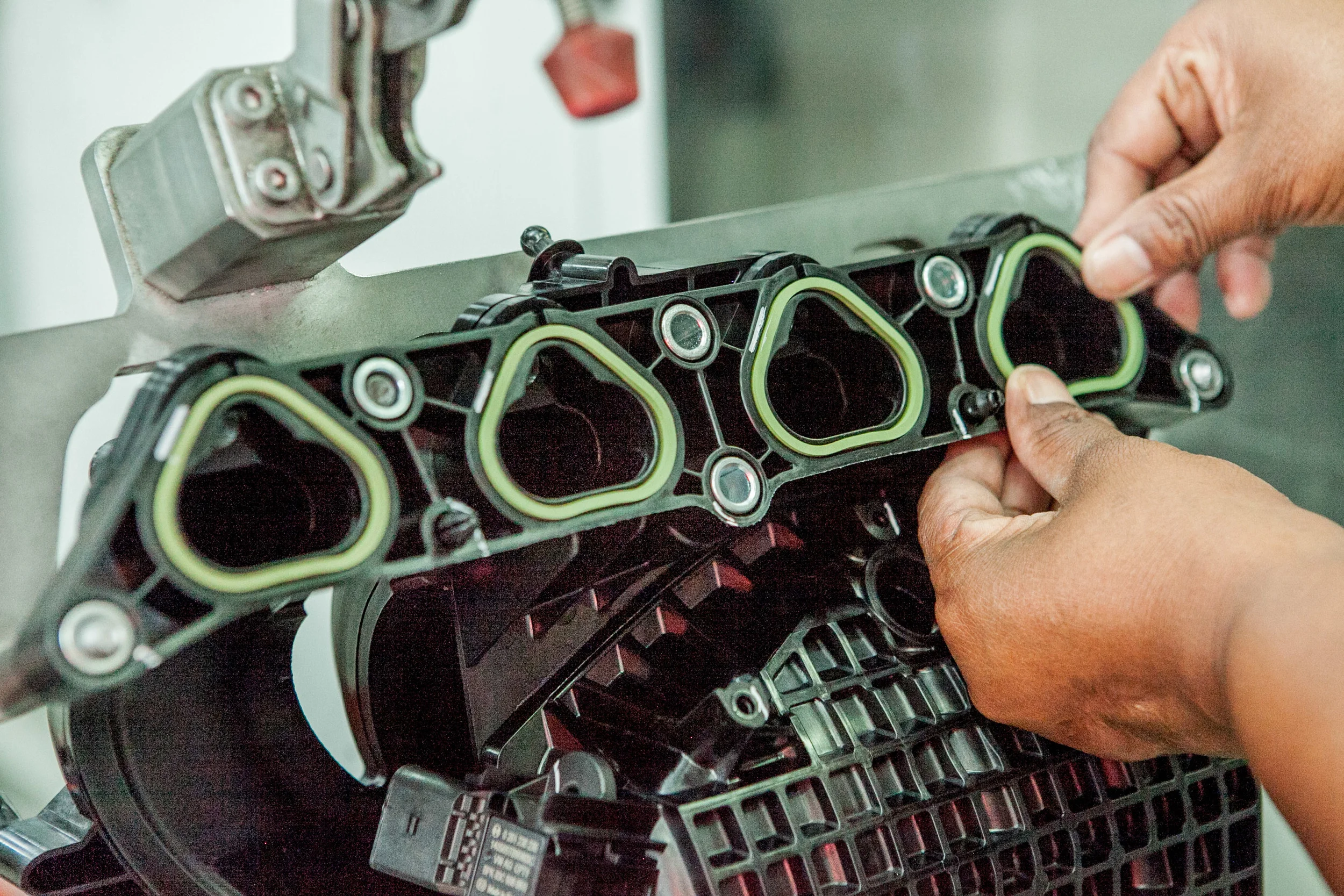

Wesley Strydom, the Technical and Project Director at Ebor elaborates, “in order to execute this work, we have had to expand our fleet and will be adding six new injection moulding presses over the next year. The first of these new presses, a 1700t Engel machine will be in operation by the end of March 2016.

To support this significant expenditure we are extremely grateful for the support of the Industrial Development Corporation who have provided Ebor with R43million rand worth of loan funding.”

Dealtry went on to explain how the additional work would create in excess of 90 new jobs in the Perseverance area of Port Elizabeth and provide a potentially very exciting ownership opportunity for every single staff member through the company Staff Trust scheme which owns 25% of Ebor.

And while everyone in the Ebor management team is completely focussed on ensuring the successful execution of the current basket of new work, there is still an air of expectation around the significant un-utilised capacity still available particularly in several of the smaller machines and in the team’s historically strong area of assembly.

January 2016